Sustainability Practices

Northern Contours is committed to our environment and the principle of sustainability.

We have allocated resources to the continued research of product options, energy savings,

recycling and other avenues that help to reduce our impact on the environment. It is our

goal to have working knowledge of current concerns and to educate our internal staff, sales representatives and customers.

Here are some of the ways Northern Contours demonstrates our commitment to the environment through our products and processes:

Here are some of the ways Northern Contours demonstrates our commitment to the environment through our products and processes:

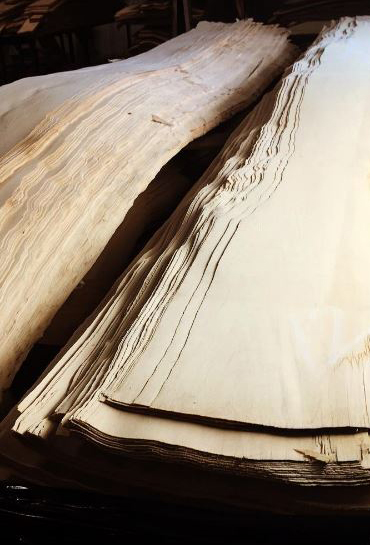

- We utilize Wood Veneer products, an ecologically responsible way of utilizing hardwood resources.

- We utilize Reconstituted Wood Veneer species, which replicate the grain and color of wood species currently under environmental pressure.

- Our composite cores are made from recycled and recovered wood waste that would otherwise be burned or thrown into a landfill. All composite cores meet CPA ECC 4-11 standards. The principle requirement for ECC certification is compliance with the utilization of 100% recovered or recycle draw materials, and adherence to CARB formaldehyde standards.

- Northern Contours products are CARB Phase 2 compliant.

- Co-polyester films, which have safer burning characteristics than PVC, are available in a selection of colors and by request.

- Finished membrane pressed components have consistently met GREENGUARD requirements for formaldehyde emissions (per customer initiated tests).

- Ultra-Low Emitting Formaldehyde (ULEF) core is available by request.

- Northern Contours works with board vendors that are FSC (Forestry Steward Council) members.

-

Our Recycling efforts:

- PVC (the unused portion) is recycled into second-generation products including packaging, pipe, siding, floor tiles, notebook covers and more.

- Composite core scraps are processed and sold to local farmers for animal bedding.

- Northern Contours recycles unused foil, cardboard, paper, plastic and cans.